LnT Kodlu LNG taşıma tankları, ulusal ve uluslararası şartlara uygun olarak tasarlanır, imalatı yapılır, test edilir ve kontrol edilir. EN 13458 / ADR ve daha fazla Avrupa onayları ile mevcut ISISAN tankları, dünya çapında kullanılmaktadır. Bütün modeller π işaretlidir. LnT Kodlu LNG taşıma tankları semi-treyler veya kamyon üzeri taşıma tankı olarak üretilmektedir. Maksimum güvenlik için paslanmaz çelik kaldırma mapaları kullanılmaktadır.

LNG TANKLARI KEŞFET

ISISAN TANKLARIN ÖNE ÇIKAN ÖZELLİKLERİ

- LnT series tanker bobtail and semitrailer are designed for the road transport with super insulations for long-term storage of extreme cold liquids with high quality vacuum level and low evaporation rate.

- Low operation costs by the high payload to tare weight with optimization of the every area of the design and the materials utilized.

- Safety and comfortable operation because of, improved ergonomics design and easily accessible valves in servicing.

- Low operation cost by using the powerful pumps decreased unloading time and powerful pressure raising unit ensures faster pressurization.

- Take care of the low centre of the gravity improved road handling and excellent stability for more safety transportation.

- Long term durability and reliability because of all steel design, stainless control piping’s, valves and welded connections, equipment supplied by the leaders in each area.

- High performance safety system with dual relief valves and rupture discs by the diverter valves as standard.

- Next to our range of standard transport tanks, ISISAN can provide you with a wide range of tailor made transport solutions likely regulatory requirements.

- ISISAN tankers are designed and manufactured in accordance with the latest international regulations such as ADR and the TPED have been incorporated or other national regulations, as required.

- ISISAN cryogenic tanker manufacturer facility is ISO 9000 approved to assure the best quality in all aspects of our operation.

TASARIM ÖZELLİKLERİ

| Tasarım Kodu | EN 13530 – ADR / TPED (2010/35/EU/ ) | |||

| Maks. İzin Verilen Çalışma Basıncı | 6 bar | |||

| Tasarım Basıncı | -196°C | |||

| İç Kap Malzemesi | Paslanmaz Çelik (EN 10028-7) | |||

| Dış Kap Malzemesi | Karbon Çelik (En 10025/EN10028-3) | |||

| Yalıtım | Süper Yalıtım & Vakum | |||

Yarı Römork | |||||||||

| Tank Hacmi | m3 | 50 | 52 | ||||||

| Net Su Katasitesi | It | 49600 | 51950 | ||||||

| Boş Tank Ağırlığı | kg | 12700 | 13400 | ||||||

| Sıvı (0.5 Barg) | kg | 20300 | 21260 | ||||||

| Toplam | kg | 40000 | 41660 | ||||||

Tabloda verilen veriler nominal hacimlerdir ve üretim toleransları nedeniyle gerçek kapasite bunlardan farklılık gösterebilir.

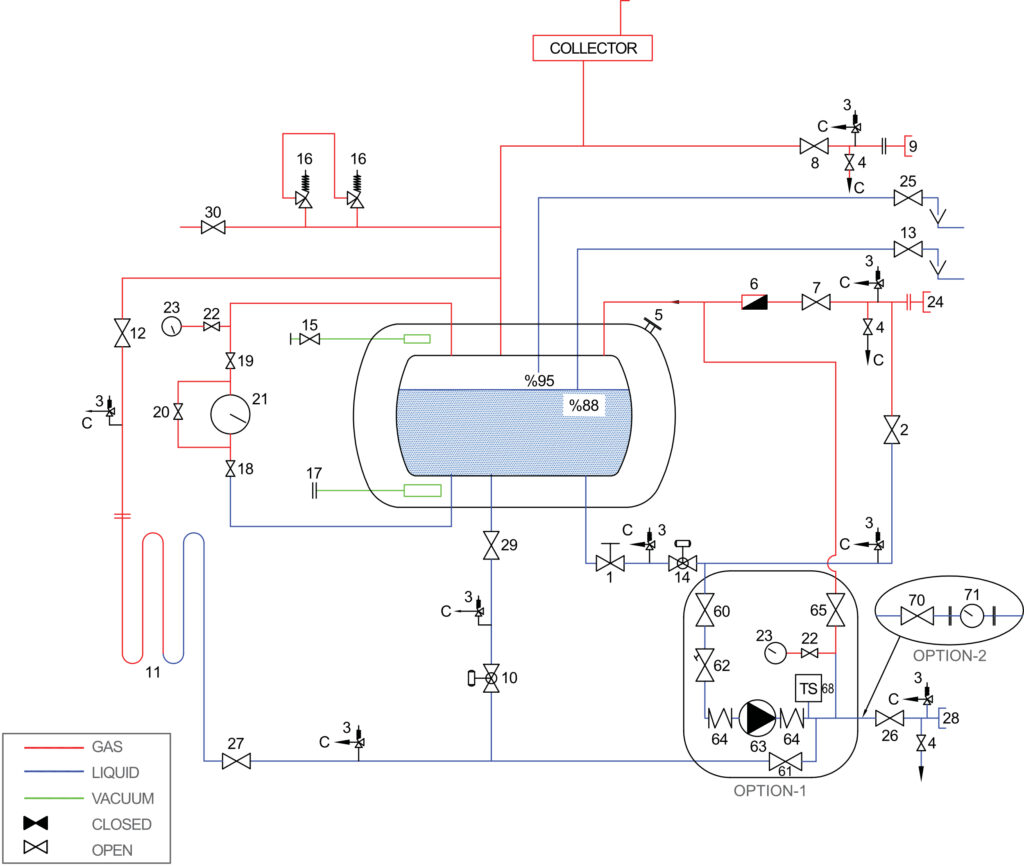

P&ID

ISISAN reserves the right to change above specifications without prior notive.

NOMENCLATURE | |||||

| 1 | Bottom Fill Isolating Valve | 16 | Inner Vessel Safety Relief Valve | OPTION-1 Pump System | |

| 2 | Bottom Fill Valve | 17 | Evacuation Connection | 22 | Pressure Indicator Valve |

| 3 | Thermal Relief Valve | 18 | High Pressure Shut Off Valve | 23 | Pressure Indicator |

| 4 | Purge Valve | 19 | Low Pressure Shut Off Valve | 60 | Pump Suction Valve |

| 5 | Vacuum Safety Valve | 20 | Equalizer Valve | 61 | Pressure Build-up Valve |

| 6 | Non Reutrn Valve | 21 | Level Indicator | 62 | Filter |

| 7 | Top Fill Valve | 22 | Pressure Indicator Valve | 63 | Pump |

| 8 | Vapor Equalizing Valve | 23 | Pressure Indicator | 64 | Expansion Joint |

| 9 | Vapor Equalizing Connection | 24 | Fill Connection | 65 | Gas Purge Valve |

| 10 | Emergency Shut Off Valve | 25 | Try Cock Valve | 68 | Temperature Probe Safety Device |

| 11 | Pressure Building Coil | 26 | Liquid Withdrawal Valve | OPTION-2 Flowmeter System | |

| 12 | Vapor Outlet Valve for PBC | 27 | Pressure Build-up Valve | 70 | Flowmeter Isolating Valve |

| 13 | Try Cock Valve | 28 | Liquid Withdrawal Connection | 71 | Flowmeter |

| 14 | Emergency Shut Off Valve | 29 | Isolating Valve for PBC | ||

| 15 | Evacuation Valve | 30 | Vapor Vent Valve | ||